Driving On-Site Action with Intermediate Goals! Improvement Techniques for Effective PMs Using Future Reality Trees

Back to TopTo reach a broader audience, this article has been translated from Japanese.

You can find the original version here.

Introduction

#In our previous article, “Problem-Solving Method Using Cause-and-Effect Diagrams | Practical Steps for Effective PMs to Improve On-Site”, we explained how to visualize on-site problems and derive solutions from root causes.

In this follow-up article, we introduce a method for leveraging the Future Reality Tree to set goals and translate them into an execution plan. We will proceed through the following three steps, incorporating case studies from actual consulting engagements.

- Step1: Clarify "Intermediate Goals" with a Future Reality Tree

- Step2: How to Create an Actionable Improvement Plan

- Step3: Effect Verification and Revisiting Causal Relationships

1. Clarify "Intermediate Goals" with a Future Reality Tree

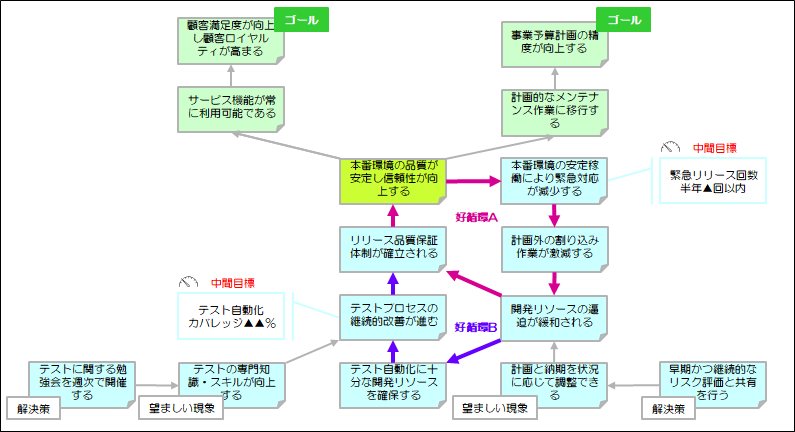

#A Future Reality Tree is a method that replaces the root causes in the current reality tree with desired states and maps out the causal relationships up to the goal. In this process, you set intermediate goals.

Role of Intermediate Goals

#- Clarify checkpoints on the path to the goal

- Serve as a standard for all stakeholders to share progress

- Be used to prioritize and ensure consistency of measures

Note: If the connection between intermediate goals and the final goal is unclear, review the causal structure. Also, updating the current reality tree periodically allows you to adapt to changing on-site conditions.

2. How to Create an Actionable Improvement Plan

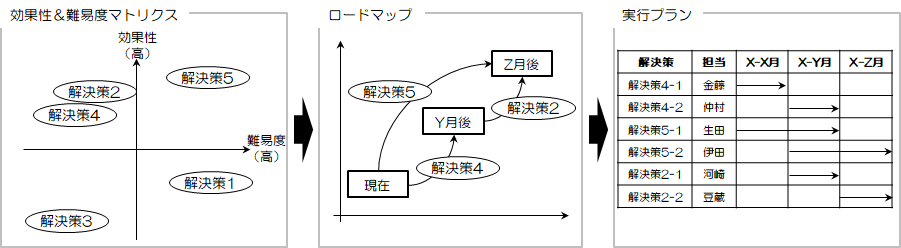

#For an improvement plan, it's important to break down ideas into “who will do what by when.”

Creation Steps

#- Organize by impact and implementation difficulty

→ Prioritize measures that deliver significant short-term impact - Clarify required resources and skills

- Create a roadmap (including mid- and long-term perspectives)

- Appoint responsible parties and set deadlines

Key point: Short-term measures are implemented to deliver quick results, while long-term measures address structural issues at their root. Ideally, combine both.

3. Effect Verification and Revisiting Causal Relationships

#To enhance the effectiveness of the plan, convert intermediate goals into quantitative metrics.

Examples of Metrics

#- Test automation rate: target 80% / actual 72%

- Emergency release count: within six months ≤ 3 / actual 5

If not achieved, check the following:

- Whether the causal relationship hypothesis is incorrect

- Whether there were flaws in the execution process

Return to root cause analysis and revise the plan as necessary.

Case Study: Problem-Solving Process in a Consulting Engagement

#Background and Challenges

#A client company had been working on process improvement for many years. However, management voiced concerns that “improvements were not taking hold.”

The business goals were to strengthen manufacturing capabilities and accelerate product commercialization. We were asked to analyze the structural issues hindering these objectives.

Visualizing the Problem Structure with a Current Reality Tree

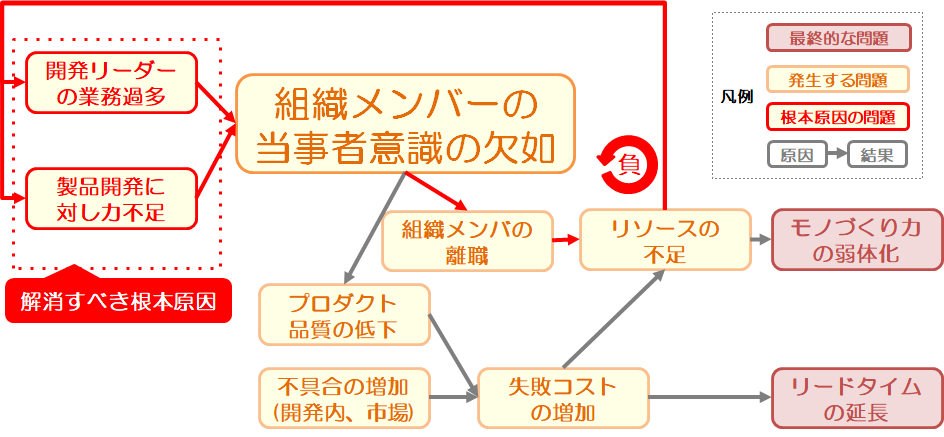

#The current reality tree visualized the complex problem structures and negative spirals lurking within the organization. Through interviews and deliverable analyses, the following issues became clear:

- Overload of development leaders

Pending issues and reviews were delayed, making the leadership layer a bottleneck. - Tool management becoming a formality

Redundant management in Redmine and Excel was occurring, exacerbating the workload. - Lack of talent development mechanisms

Systematic skill development was not happening, resulting in underqualified team members. - Inadequate project management control

Due to insufficient internal capabilities, there was increased wholesale outsourcing to partner companies, and lax subcontractor management led to frequent plan deviations. - Weak sense of ownership toward the product

An increase in makeshift tasks contributed to a decline in quality.

The Reality of the Negative Spirals

#When organizing the issues, they boiled down to two root causes: “overload of development leaders” and “insufficient product development capabilities.” These generated the following two negative spirals:

- Spiral 1

Work overload → Decreased sense of responsibility → Turnover → Resource shortage - Spiral 2

Skill shortage → Quality decline → Increased defects → Higher failure costs

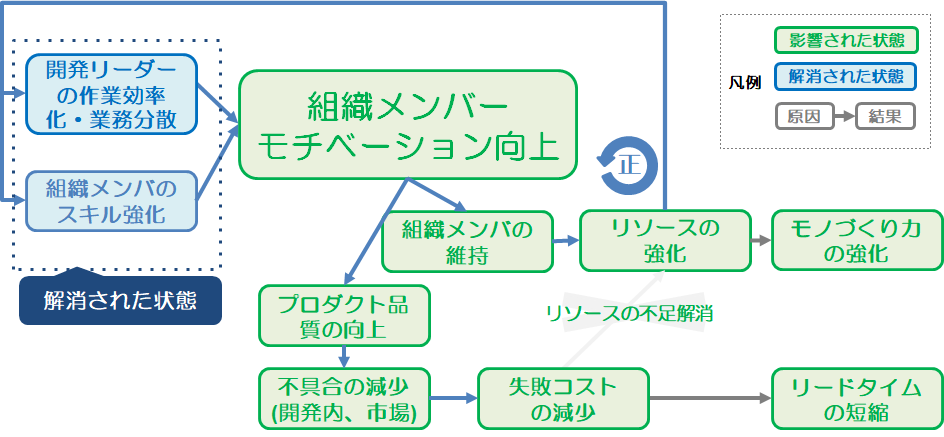

Designing a Future Reality Tree and Positive Spirals

#Based on the causal relationships transformed into “desired states,” we mapped out the formation of positive spirals and the path to the business goals. To break the negative spirals, we replaced them with the following “desired states”:

- Distribution of workload

- Skill enhancement for team members

- Establishment of a product development system with a strong sense of ownership

This enabled the formation of positive spirals and clarified the path to achieving the business goals.

Detailing Solutions | Short-Term and Long-Term Improvement Approaches

#To address the root causes, we examined and implemented the following solutions:

| Root Cause to Eliminate | Resolved State | Solutions to Eliminate |

|---|---|---|

| Overload of development leaders | Work distribution and efficiency gains | Procure external PMs, introduce PM support tools |

| Insufficient product development capabilities | Skill enhancement | Formulate development plans, design training programs |

In the short term, we focused on removing bottlenecks; in the long term, we advanced structural improvements through development strategies.

Conclusion | Execution Strategies to Link Problem-Solving with Results

#In this article, we explained the process that starts with the future vision drawn in a cause-and-effect diagram and leads to problem-solving through the setting of intermediate goals and drafting of execution plans. To guide “visualized” problems toward “resolution,” a loop of execution and verification is essential.

Don’t stop at simply visualizing the problems. Translating solutions into action is the first step toward on-site improvement.

This article is part of the "Effective PM Series"

👉 Preventing Checklists from Becoming Formalities! Reconstruction Techniques and 7 Improvement Measures for Effective PMs

👉 How to Conduct Regular Meetings Without Becoming Formalities | 7 Improvement Steps for Effective PMs

👉 List Management That Ensures Issue Resolution | 12 De-Formalization Techniques for Effective PMs

👉 Problem-Solving Method Using Cause-and-Effect Diagrams | Practical Steps for Effective PMs to Improve On-Site

👉 Practical Steps for Process Improvement | The IDEAL Model Used by Effective PMs and Secrets to Success